How to Draw Up a Deck Plan

If y'all're a regular reader, you lot know this detailed guide is the culmination of many days shadowing expert general contractor and carpenter Steve Wartman. I was on-site as he and his crew built this deck, taking pictures of the progress, documenting the piece of work and discovering tips and tricks. I'm convinced that in that location's no meliorate style to learn how to tackle dwelling house improvement projects than following a licensed contractor through a build. If you enjoy this article, check out our other Project Guides. To stay electric current on all our Pro-Follows, subscribe via RSS or email.

If you live in the greater Baltimore area and are considering adding a deck to your home (or whatever other sort of home improvements), I suggest you give Steve a call. This article is a great example of the high quality and professionalism that Steve and his coiffure bring to every job. For more examples, check out our articles on building a shed or how to hang drywall.

How to Build a Freestanding, Blended Deck

The same homeowners that had Steve'southward crew build a custom shed accept contracted him once more to construct a new, blended deck on the back of their abode. They went with Trex brand composite materials for the build, because Trex is virtually maintenance gratis, significant the homeowners won't ever demand to seal, burnish or strip the decking boards.

The Plan

Here's Steve to requite y'all a short introduction to this project.

Video Summary: Steve describes a plan to build a new, 12 x 24′ deck and a 4′ set of stairs. Information technology'll take two rows of buried posts, Trex composite decking, Trex trim boards and a white vinyl rail system.

Step ane: Plan, Dig and Cascade the Footers

Determining the location of the deck was easy. Information technology was more than difficult to make up one's mind how many footers were required and where they were going to be located. This video shares some details most footer and ledger board requirements.

Video Summary: How the deck attaches to the house is one of the factors that determines the required number of deck posts and footers. Other considerations include the size and shape of your deck, how much weight it will hold, and the size of the beams. This deck is rectangular in shape, and the homeowners aren't planning on adding a hot tub (or other heavy objects). Since Steve's crew couldn't through-bolt the ledger board, they've installed ii rows of posts, creating a "gratis-standing deck."

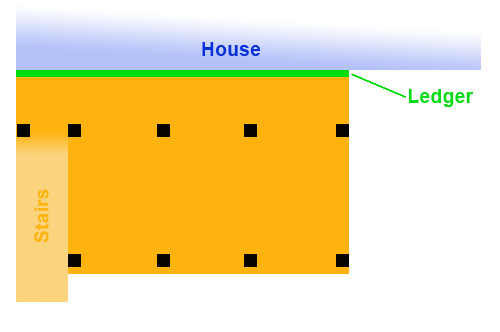

The first row of posts was placed 3′ off the business firm, and the second row of posts was viii′ after that. Posts are spaced no more than 8′ apart then that ways we have four posts per row, with the first row having 1 additional postal service to account for the stairs. Here'south a sketch of the deck and posts.

After Steve determined the footer locations, the crew ran several cord guides and started earthworks. This was no small job considering they decided to cut through the brick patio and underlying concrete before learning it was five-1/2″ thick.

Each footer needed to be deeper than the frost line, and here in Maryland that means footers must be at least 30″ deep. In areas such as northern Minnesota, footers need to be at least 60″ deep, then check the lawmaking for your area before digging. Steve'southward coiffure dug each hole about 24″ across. Before continuing, all the footers needed to pass inspection. In this jurisdiction, this was the merely required acting inspection, and the checklist includes:

- there are a sufficient number of footers to properly support the deck

- the footers are spaced appropriately

- the footers are dug to the proper depth (thirty″), which is the depth required to exist beneath the frost line in this region

Pro-Tip: Before you start digging, have underground lines (water, gas, ability, communication, etc.) located. Call the Due north America I Telephone call Referral Service (one-888-258-0808). Information technology's gratuitous and required by law.

The inspection went smoothly, and Steve's crew started pouring the footers. Using 80lb. bags, they mixed enough concrete to achieve an 8″ thick pad.

They used a garden hoe to make sure the concrete would prepare with a nice, apartment surface.

Stride 2: Install the Ledger Board

While the concrete cured, the guys started on the ledger lath. They installed a two x 10′ ledger along the entire length of the deck, taking intendance to ensure it was completely level. Steve and his crew temporarily secured information technology in place using a powder charge nailer. Here'south a quick demonstration:

Video Summary: In the video, Steve shares how driving temporary anchors makes it easier to install the ledger board. For this brick and masonry firm, you accept to use concrete fasteners, and a powder accuse gun really uses a .22 caliber shot to quickly drive the anchor. It's important to pre-drill a hole so you lot don't split the board which besides enables the nail to become farther. That'southward how they temporarily set up their ledger board.

Next, the crew marked the locations of their joists. Often you'll see joists spaced at 24″ on heart (oc); however, with blended decking, joists need to exist closer together. Steve's crew marked their joists at 12″ oc. Predetermining the joist locations ensured that none of the physical anchors will create an obstacle, and it allowed them to identify an anchor in every bay (betwixt each joist).

The crew used physical anchors called Blood-red Heads to secure the ledger board.

The concrete anchors needed to exist staggered and, for the upper row, driven into the mortar between bricks. For each Red Head, the guys pre-drilled a hole, used a hammer to bulldoze them in place, and a socket wrench to tighten them down.

Step 3: Install Deck Posts and Beams

The coiffure used force per unit area treated half-dozen ten vi″ for posts on this deck. These were rated for "ground contact", which, every bit you might expect, means they can be cached directly in the ground.

Pro-Tip: Force per unit area-treated lumber is infused with chemical and rated past the amount per cubic pes of wood. Ground-contact lumber has .40 pounds of preservative per cubic foot, and above-basis rated lumber has .25 pounds.

Pro-Tip: The size of posts required for a deck installation depends on the span being supported by the post, as well as the height of the deck. Steve'due south crew prefers vi x vi″ posts for their sturdiness; however, four ten iv″s may be used in certain depression-acme installations. In certain very tall installations, cross-members may be required between the posts for added support and to preclude racking.

The challenges with installing deck posts include keeping each mail service:

- square with the business firm

- square with all other posts

- the right distance from the house

- notched at the proper height to support the beams and joists, ensuring an acceptable slope abroad from the house

The crew moved the get-go post into place and marked a line indicating the very top of the post which was even with the support axle. The reference point on the ledger board was the lesser of the floor joists.

Using a circular saw, they cutting the mail service to the proper meridian, based on the previous measurement.

Using a reciprocating saw, the coiffure cut a notch for the support beam so that the top of the postal service was flush with the support axle.

The support beams consisted of two, 2 10 10″ boards nailed (and later bolted) together, side-past-side in the notch.

Pro-Tip: You lot may see support beams where the deck post is sandwiched betwixt ii pieces of 2x material. The method we describe here is better, because when the ii boards are touching, they deed as a unmarried unit. Furthermore, separating the 2x material requires boosted blocking in between the joists to support bolting, and therefore, longer bolts.

With the postal service cut to the appropriate dimensions, the crew moved it into place, and secured it with temporary boards. This was a tedious activity that required several pairs of hands and repeated measurements, but information technology was extremely of import for the finished product.

The crew repeated the procedure for the middle postal service, and, afterward it was in place, added one of the 2 x ten″s that will makeup the support beam. This allowed them to double-bank check level and altitude from the house across the entire gap, and make adjustments every bit needed to each post.

Again, the level was aligned just like a flooring joist so that the peak of the floor joist sat flush with the top of the ledger.

This process continued for all 5 posts in the first row along the house. The middle post was where two support beams butted against each other. The transition was accomplished past equally dividing the infinite in the notch between the two beams.

In this picture, you lot can see all the temporary boards that kept the posts and support beam in identify.

Once the crew was satisfied with the unabridged row, they back filled the dirt and tamped it down, taking intendance non to movement the postal service. Any movement required additional measurements to ensure nothing moved out of square with the house or the other posts, and that the post was still at the proper height.

The second row of posts went in much the same fashion except for one thing. Since the crew had the ledger and first row finished, they added a few joists and ran a string guide to make it easier to setup the rest of the posts. It's also important to annotation that they established a 3/eight″ slope (over the entire width) to direct water away from the firm.

Once the coiffure had set a few more posts, they ran a record measure along the diagonals to bank check for foursquare.

This picture shows a coiffure member adding that 2d 2 ten ten″ to form the back up axle.

These ii axle components were later secured with staggered carriage bolts through the mail service.

Step 4: Install Flooring Joists

Since the ledger was already marked, lining up the joists was not a difficult task.

Hither yous can encounter the crew once again made sure the joists were square to the ledger. The importance of re-checking square measurements cannot be overstated in a deck build. If components showtime out of square, information technology volition be hard to make the deck look good at the finish.

Pro-Tip: Joists should always be placed "crown up" in an installation. All joists must be oriented identically in this mode to ensure the deck won't have waves betwixt the joists. In our tutorial on How to Build a Shed, nosotros provide a video on checking and marking dimension lumber to identify the crown.

The crew did intermission out a planer at 1 bespeak because they establish a few boards were thicker than the others.

Pro-Tip: Double-cheque board dimensions, considering you may find some variation in your lumber package. Never presume that all joists are exactly the aforementioned dimensions. Purchasing actress lumber allows you lot to be more than finicky and avoid using bawl-cut or bowed boards.

Each joist was toe-nailed in identify with 4 nails, and so a Simpson hanger tie was added.

It was fun to encounter the coiffure use this palm nailer for fastening the hanger ties. Information technology made driving the ten nails into the hanger very quick–much quicker than could be achieved with a regular hammer, which is an adequate (albeit much slower) alternative.

The guys used Simpson nails with the hanger ties. The shorter nails (N10) secured the hanger to the ledger, while the longer nails (10d) were used for the angled slots. Using the correct nails for hanger ties is very of import, as the strength of the hanger is dependent on using the appropriate hardware.

Equally you may call up, the crew planned the joist spacing at 12″ oc since they were installing a manufactured blended decking surface. For traditional 5/4 pressure treated wood surface deck, 16″ oc is more common. Joist spacing depends on both surface material every bit well every bit spanning altitude betwixt the posts.

Pro-Talk: The term "v/four lumber" is shorthand for lumber that is nominally 1.25″ thick (or 5/4s of an inch). 5/iv lumber is actually finished to 1-1/16″. The blazon of 5/4 lumber used on decks has rounded edges and is known as "decking board". Composite decking cloth is generally the aforementioned size as five/4 lumber (or close to it).

Pro-Tip: Overhead ability lines must have at least ten′ of clearance. These lines will later be buried to meet that requirement.

Step 5: Add the Band Board to the Joists

The crew got all the joists set in identify and secured with joist hangers, including a double-joist in the middle. Since the deck was 24′ long, the band board consisted of two 2 ten 8″due south butted against each other, and the transition at the double joist.

Using a string guide, the guys marked the ends of each joist and cut away the excess with a round saw.

The band board was situated between the rim joists and secured with four nails per joist. Notation that the last joist was 1.five″ longer to remain flush with the band board. This immune nailing from the side of the joist into the board.

Pro-Talk: A rim joist, or band board, is the final joist that caps the end of the row of joists that support a floor.

Step 6: Install Blocking Between the Joists

Blocking in between the joists provided a surface to mount the rail organisation. This was especially important because they planned to "picture frame" the perimeter to conceal the cut ends of the composite deck boards. To reach this, the crew cut pieces of two x 4″ to fit in between joists and sistered a two x 4″ forth each rim joist.

Footstep 7: Build the Stairs

Edifice the stairs was not an overly difficult procedure; the key to success was making accurate cuts. In this curt video, Steve shares how he calculated the stair stringer dimensions.

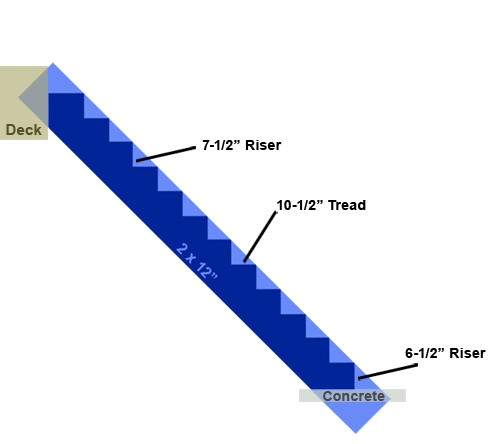

Video Summary: Steve describes how he started the procedure to build the stairs by beginning determining the total height of the stairs. Stair risers need to exist between seven and 7-three/4″ tall, and using vii-1/2″ translates into 12 risers. Likewise, stair treads need to be between ten and 11-ane/4″ wide. Since they volition accept 12 steps, the tread needs to be x-1/ii″ with a 3/4″ overhang. If this notwithstanding seems confusing, Todd from Home Construction Improvement has a very simple Stair Stringer Calculator spreadsheet you can download for complimentary.

With the ascension and run dimensions calculated, it was time to mark the stringer. Sentry this short video for more information about marking the 2 x 12″.

Video Summary: This video shows how to scribe the stair stringers. It'southward important to cheque the crown of the board and make sure it's "crown upwards." Using a framing square, line up the rise and run measurements on the edge of the stringer and marker your line. Then yous move down and repeat the process. Lastly, extend the first line (riser) through the ii x 12″ and cut off the backlog.

I put together these diagrams to help visualize the stringers. Yous'll find that the very final step is 1″ shorter. That's because there are no deck boards on the concrete, and shortening that riser keeps each pace height consistent.

The stairs measured iv′ across and to maintain the 12″ oc supports they volition needed a total of v stringers.

The two outside stringers were slightly longer then that the cantankerous member was situated in-between them. The inside stringers butted up against the cross-member, and this was of import because it allowed Steve's crew to bulldoze nails in two dimensions for a more secure hold.

These pictures show how the guys assembled the stairs.

In the diagram above you lot run into mention of a physical pad. It's of import to have something solid at the bottom then the stairs don't just sit on the ground which will erode over fourth dimension. While edifice the stairs, the guys also congenital a physical form and poured a small physical pad.

This pad had ii "footers" where the stair rail posts volition be situated.

Hither are a couple of shots showing the stair landing. It measured approximately 4 x 4′, and the joists and ring board were installed only like the rest of the deck.

After the concrete cured, they moved the stairs into place with the top of the stairs resting on the deck support axle.

Steve'southward coiffure checked that the stringers were level so nailed them in place.

Step viii: Wink the Ledger Board

Contractors use flashing to foreclose water and wet from finding their style into a abode. The general idea is that since h2o flows downward with gravity, yous tin can overlap waterproof membranes (like siding, stucco, metal flashing etc.) that volition straight water away from the house. Improperly flashed decks can cause a lot of bug, because leaks may not be visible right away, and they are not ever readily diagnosed. Furthermore, making repairs afterward a deck is finished tin be a very onerous task. (Although some deck structure methods make it easier to address such challenges than others. Nosotros talk about that below.)

The Unique State of affairs with this Deck: The exterior of the house is a combination of brick and cake. The ledger board was fastened to the brick, which is already constantly exchanging moisture with the outside globe. Since the masonry anchors Steve used did not penetrate deep plenty into the brick to disrupt the moisture barrier, Steve's crew was confident that this deck did not crave separate flashing. (There is no path for water to enter the dwelling house.) Typically, the crew would err on the safe side and flash anyway; yet, in this installation flashing would take been visible and would have detracted from the look of the finished product.

This state of affairs with this deck is unique because the ledger board in this design was not a load bearing element. This deck is freestanding, with two sets of posts and beams on which the joists sit down. In nearly decks, the ledger board is load bearing, and the bolts go all the style through the rim joist of the house. This situation always requires flashing to prevent leaks, and it's recommended that holes drilled for bolts should exist filled with a silicone sealant. Wait for helpful links including 2012 International Building Code (IBC) and International Residential Code (IRC) in our Related Content department at the end of the post.

If the crew had decided to flash the deck, here's how they would accept washed it:

- Trench out one of the horizontal mortar joints above the ledger board enough to insert an inch of copper flashing.

- Before inserting the flashing, curve a small double-back hem that will act equally a wedge between the bricks.

- After inserting the flashing, seal the joint with a flexible sealant.

- Make certain the flashing extends downwardly over the ledger board.

- Cut the flashing at each floor joist in order to become the flashing between joists to curve.

Pro-Tip: Newer chemicals for pressure treated wood similar alkaline copper quaternary (ACQ) and copper azole, are more corrosive, and aluminum flashing and steel z flashing actually deteriorate when in abiding contact. For that reason, apply a prophylactic or copper flashing product. Ane reader also suggests using 1.five″ wide strips of #15 building paper betwixt the two can besides prevent problems.

Footstep ix: Lay the Composite Deck Boards

Steve'due south crew installed Trex Transcend composite decking boards for this build. The homeowners were really excited about this, because composite decking is nigh completely maintenance free. They won't ever have to worry almost sealing, stripping or brightening the boards. The band board and stair risers will be wrapped in a white, Trex composite trim.

Trex is a capped-stock, which means the cadre of the lath is composed of a dissimilar material. For that reason, exposed ends are especially undesirable, and Steve's crew created a "film frame" around the perimeter to conceal the board ends.

The guys knew that the firm wall was non 100% direct so they ripped the first piece of Trex in such a way as to eliminate as much inconsistency as possible.

They cutting a 22.5° scarf joint to muffle the transition from i board to the next.

Pro-Talk: A scarf joint is made by overlapping two pieces of woods along a tapered, beveled, or chamfered end.

Steve's crew used screws designed for composite decking. If you wait closely, yous'll notice that the top is reverse threaded which holds the screw in place while the screw-head acts as more of a plug.

Screwing downward the deck boards was slow going because each screw needed to exist pre-drilled to prevent the board from condign disfigured. Besides the added cost of materials themselves, this step made the installation of composite decking more expensive than the installation of traditional pressure treated products.

Afterwards the guys set ii adjacent pieces of the "picture frame" in place, they started laying the diagonal boards. It was important that the start board be laid accurately, because they acted every bit a indicate of reference for all of the others.

Steve'south coiffure cuts the finish at a 45° and measured the contrary side to ensure the angle stays true.

Each board was secured with two screws at every joist.

Pro-Tip: You lot can opt for hidden fasteners that are driven into the side (rather than the face) of the deck boards. This requires a specialized jig and incurs some actress cost.

All decking (composite and traditional) volition expand and contract with changes in weather, and it's of import to adequately infinite each board to provide that necessary room. To achieve a uniform spacing, Steve'south crew sets up a cake with 8d nails to create the gap.

This picture shows the progress after a few rows have been laid.

Pro-Tip: Trex composite features a forest-grain inlay to make the boards wait more similar a natural product. The woods grain is a pattern that y'all'll see repeated many times over the length of a single lath, and if you're not conscientious to stagger the pattern, it will be readily credible to anyone looking at the deck.

Afterwards the diagonal boards were in identify, these ends were trimmed with a circular saw.

Pro-Tip: Even though I describe this as a 12 x 24′ deck, it will actually measure a few inches shy of 12′. If the homeowners had truly wanted a 12′ deck, it would require Steve to purchase xx′ composite boards since they're being installed diagonally, and that jumps the price upwardly significantly. By making the deck simply a little shorter, Steve can purchase 16′ composite boards and provide a more cost-effective solution.

Here are some images that prove how the deck progressed.

They snapped a chalk to marker their line for the circular saw.

Step 10: Install Trim on the Ring Board and Stair Stringers

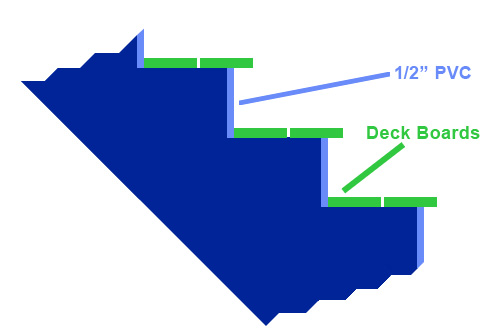

Steve's crew installed a white, two ten 12″ PVC trim board on the outside stair stringers and the band board. It gave the deck a nice, polished look and matched the rail system. PVC is nice to work with because it'due south lightweight, flexible and maintenance free. The guys mitered all the corners and used finish nails to fasten the boards.

They filled all the boom holes with a PVC putty so that you can't even see the nail hole.

To cutting the PVC to match the stair stringers, they cutting the very commencement riser and temporarily tacked the PVC confronting the stringer for marking cut lines. This was better than re-drawing the stringers because even the nearly accurate carpenter may have some variation, and this ensured that each section matched perfectly.

Editors Note: Nosotros are walking through this deck build chronologically, but stair stringer trim is best left after the treads, risers and stair guards accept been installed.

PVC is easy to cutting, and then a jigsaw makes curt piece of work of cutting out the stringer trim.

Footstep xi: Add Stair Treads and Risers

Afterwards getting the trim in identify, the guys moved onto the stair treads and risers. Every 3 or four steps, they added blocking to ensure a consistent width.

Steve's coiffure also added these blocks at the base of operations, which will have physical anchors driven into the pocket-size slab below. The two outside trophy don't have blocks because they'll have stair posts (eventually).

Starting at the top, the crew measured the riser offset, cutting a piece of PVC long enough to reach across the cut edges of the stringer trim.

Next, the crew cut the kickoff tread. You can see how that the tread does non extend the entire length. This is on purpose, because the crew left room for a return piece to conceal the cut edges of the tread.

This picture shows one of the return pieces that hasn't been fasten however. It was dull going to get all the cuts exactly correct. To help themselves out, the guys put together templates. The return pieces were secured with screws through the side of the return and into the tread board.

Some other small item that you lot might have missed is that the guys notched out the stair riser for the return piece using a Bosch multi-tool. This notching makes the tread appear to go nether the riser when viewed from the side, which creates a squeamish visual await on the staircase.

Step 12: Install the Composite Rail System

Steve's crew installed a white, vinyl rail system, and the picture below shows one of the steel posts and plastic spacers.

Remember the blocking betwixt joists around the perimeter of the deck? That blocking allowed Steve'due south crew to securely spike the steel posts with 3-5/viii″ LedgerLOKs. Each mail was leveled as necessary with shims, ensuring information technology was perfectly vertical before fastening. After the LedgerLOKs were installed, each post got a plastic spacer which serves as a guide for the PVC trim embrace.

Pro-Tip: The International Residential Code (IRC) requires rails to resist a load of 200 pounds.

Next, the guys trimmed the vinyl sleeve to the advisable tiptop and slipped it in identify with another plastic spacer at the top. They placed posts about every half dozen′.

Pro-Tip: Deck railings are required to be at least 36″ tall.

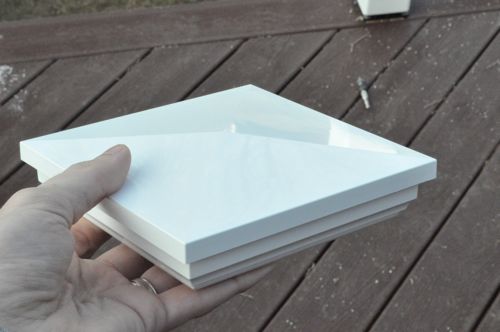

Hither's a picture of one of the post caps. These were installed last and are usually glued in place to avoid using fasteners.

Later on the posts were set, the guys slid a square, base trim piece over the vinyl sleeve to muffle the lesser of the steel post. Side by side, they cut the lower rail to length and screwed it in identify. It's important to cut an equal corporeality from both sides of the rails to maintain a balanced appearance for the pickets.

Pro-Tip: The lower rail should exist low enough that a 4″ sphere cannot fit underneath the rail.

This rail organisation had convenient mounting brackets for the upper and lower rails which included plugs and caps to conceal the screw heads. After the lower rail was fastened, they inserted a picket into each hole.

The upper rail was installed in a like fashion, except for one boosted stride. The upper rail had an aluminum channel for increased strength, and Steve's coiffure needed to trim this channel to length.

The guys placed 4 x iv″ force per unit area treated posts at the bottom and middle of the stairs. The set at the bottom rested on the concrete pad and were through-bolted in identify.

The middle set ran all the way into the ground where they were secured much like the deck posts: a xxx″ deep hole, concrete footer, and backfilled with dirt. They also through-bolted these and had to notch the stair treads.

Each post was cutting at 36″ and a vinyl sleeve was fit overtop.

The stair kit had angled brackets. However, the guys needed to cut the pigsty for the picket.

Steve's crew cut the upper and lower rails at a 35° angle, and trimmed them to length with equal portions cut from both sides to maintain an even appearance. The holes on the upper and lower rails were slightly bigger to allow the pickets to stand plumb.

Code requires a continuous handrail so they added this metal-core rails on the correct side to meet that need.

Last Pictures

Here are several pictures of the finished product. This deck looks fantastic, and will be excellent for entertaining and enjoying the outdoors.

Special thanks to readers Jeff Williams, Icarus, Haus356, William, MissFixIt, Joe, Jake, Eek565, JD, Reuben Collins, Simon, and John. Without bully questions and comments, this how-to wouldn't exist about as complete.

hendricksoncarapt.blogspot.com

Source: https://www.oneprojectcloser.com/how-to-build-freestanding-deck/

0 Response to "How to Draw Up a Deck Plan"

Post a Comment